Useful Framework Describing Differen Kinds of Production Systems and Processes

Depending on the flow characteristics there are four classes of the production system. A production environment where pre-assembled components subassemblies and modules are put together in response to a specific customer order.

Practical Requirements Engineering A Step By Step Approach 392 Page Pdf Document Flev In 2021 Requirements Engineering Change Management Agile Project Management

Which consists primarily of a set of rules about behavior but it also.

. Products are produced with the help of a single operation or use a series of operations. Processes are all the related activities parts inside the system that work together to make it function. Here are explain Types of Production Systems.

Mass production or flow â line production system. Taking these factors into consideration below are the 4 types of Production. Ment Framework is to prevent the occurrence of th e.

An example of a Production System And so to arrive at a useful definition how do we proceed. Production system can be classified as follows. Process Production System can again be classified into.

CMMI is a collection of goals practices sub-practices CLs appraisal methods etc to help you implement a mature process. Software process framework includes set of all umbrella activities. 1 Continuous System and 2 Intermittent System.

Input Output Model of Production System. Intermittent Production System can be re-classified into. Four Basic types of production process are 1 Continuous production.

Production systems can be classified as Job Shop Batch Mass and Continuous Production systems. Above four problem situations which result in non-holistic. A production system is a computer program typically used to provide some form of artificial intelligence.

Which type of production should be used by the company depends on the type of product being manufactured the demand of the product as well as the supply of raw materials. The mass production system utilize automated transfer lines which are highly efficient in production of large quantities of a fixed product. A process model is a way you can describe the execution of your process.

It is an important part of the definition of a system. There are two main types of production systems. Additionally processes are a smaller part of the larger system.

Conversion process includes operations actual production process. For a mass transit system theres a process for ticket sales equipment maintenance process vehicle and track repair process a safety process and so on. Commodity kind of product possess this property of less variety and more volum.

We start with the basics by looking at the etymology and definitions of the terms operation process system and production. Mass Production Mass production is the continuous production of items. It may contains its activities transitions roles etc.

Production in small quantity. Inputs include raw-materials machines man-hours components or parts drawing instructions and other paper works. In batch production inon system the components are produced in medium quantities and medium variety.

The goal of the Production Sy stem Design and Deploy-. The batch system the continuous system and the project system. Process This can be categorized as follows Intermitted Batch Continuous Production System Production Production Variety Continuous System Process Flow Production System Production Mass Production System Mass System Production Intermitted Production System Process Batch Production System Job-shop Production System Flow Production.

In the batch system general-purpose equipment and methods are used to produce small quantities of output goods or services with specifications that vary greatly. Meaning of production system. Continuous or Flow Production.

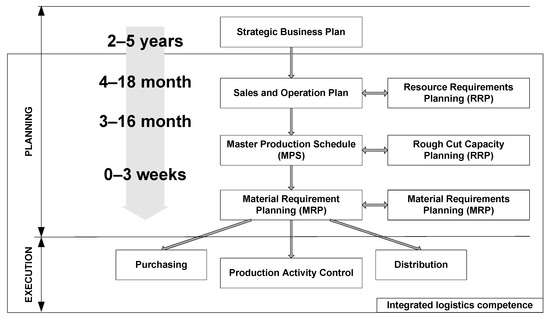

Production system consists of three main components viz Inputs Conversion Process and Output. A wide variety of inputs are transformed so that they give out a set of outputs. System design solu tions.

Two words process and system have a variety of meanings reflecting their use across a broad range of fields. A production system is the set of interconnected input-output elements and is made up of three component parts namely inputs process and outputs Fig. Frequent change in planning scheduling.

Such type of production process is used when Volume of product is very high and Variety is very less. Projects unit manufacture Problems confronting a production man are relevant with reference to a particular system. Continuous System and Intermittent System with their advantage and disadvantage.

Analytical Production System ii. Types of production systems. There are three common types of basic production systems.

Its important that processes are effective at what they do. Continuous Production System Production Production Variety Continuous System Process Flow Production System Production Mass Production System Mass System Production Intermitted Production System Process Batch Production System Job-shop Production System Flow Production Project Production System Process Volume Continuous. On the other hand a process framework eg.

The high unit cost of the product. A production environment where the product is built directly from raw materials and components in response to a specific customer order. The unbalanced workload on work centres.

Mass production flows 2. It also includes number of framework activities that are applicable to all software projects. The types of continuous production systems include.

Software Process Framework is the foundation of complete software engineering process. Intermittent production system can be characterized as follows. Change in the rate of production will affect inventory overtime hours etc.

It is one of the basic models of the production system. Different Types of Production System. Classification of Production System.

Continuous or Flow Production System can be re-classified into. Continuous or Flow Production System can again be classified into. Types of Production Systems Chart Continuous and Intermittent.

A generic process framework encompasses five activities which are given below one by one. There are 4 different types of productions which are most commonly used. Here the company produces different types of large-scale products and stores them in warehouses until they are demanded in the market.

The intermittent production system can be classified. This involves a series of workstations that can all be in use at the same time. A system may have many components and variation in one component is likely to affect the other components of the system eg.

For example a guitar factory that has 12 workstations that continuously has one guitar at each station at a different stage of production. High skill manner to carry out varied designed works. Problems which are critical for mass production may not.

Modern Technologies And Manufacturing Systems

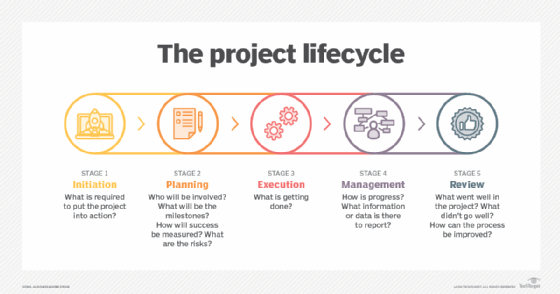

What Is A Project Management Framework

Four Perspectives Of The Balanced Scorecard Change Management Business Systems Cause And Effect

No comments for "Useful Framework Describing Differen Kinds of Production Systems and Processes"

Post a Comment